The EKOL 4 wastewater treatment plant for 25 persons is ideal for hotels, restaurants or even apartment buildings. Above all, it is the perfect device for places where, due to their location , it is not possible to connect to the sewage system.

At Morava Ekol we are able to cover a wide range of possible loads and needs of large and small numbers of people. So you can choose a sewage treatment plant for 7 people, for 15 people, for 40 people, for 60 people, for 80 people or for 100 people ideal for the needs of a given property.

Description and functions of the EKOL 4 wastewater treatment plant

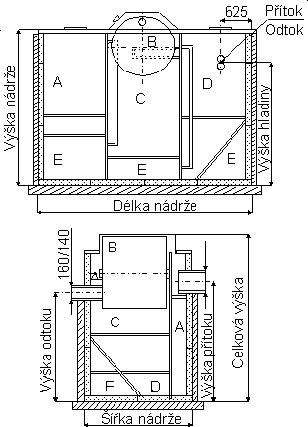

The basis of the EKOL 4 is a tank made of wall elements and polypropylene plates. The tank is enclosed by a split removable lid, which is non-penetrating and contains ventilation and clearing holes for sludge removal.

The tank is divided into a primary sedimentation - settling area (A), a storage area (E), a biological treatment area (C) with a rotating biocontactor (B) and a settling area (D). The biocontactor consists of a cage filled with small plastic elements. The rotation of the rotor is provided by a drive unit consisting of a sliding gear box, a V-belt transmission, an electric motor with a distributor.

How the EKOL 4 wastewater treatment plant works

The treatment is integrated in one packaged unit, where there is both a mechanical treatment section (A,D,E) and a biological treatment section (B,C). Mechanical treatment is carried out in a two-chamber settling tank (A) by simple sedimentation. A part of this area near the bottom is reserved for anaerobic sludge stabilisation, thickening and storage (E). Pre-treated water flows into the biological treatment area (C) where the progressive TF/SC method, first introduced in the USA 15 years ago, is used.

This treatment method uses the activity of sessile and buoyant organisms. The composition of these microorganisms is so different that they are complementary in their effects. This results in a balanced treatment effect, and at the same time a higher resistance to hydraulic and metabolic shocks compared to conventional wastewater treatment methods.

The activated mixture from the biozone (C) flows through a degassing chute into a vertical settling tank (D), which is connected to the biozone area (C) at the bottom. This ensures continuous dewatering of the settling tank (D) and the excess activated sludge is pumped back to the settling tank (A) by means of a wheel located on the periphery of the biorotor, where it is mixed with the freshly flowing polluted water.

In the settling and storage tank (A,E), the activated sludge flakes and the sludge water are separated and flow back together with the inflow to the biozone. In this way, communication between the biozone (C), the settling tank - septic tank (A) and the settling tank (D) is ensured. The clean water outlet trough from the settling tank (D) is equipped with adjustable brick walls to prevent floating suspended solids from the surface of the settling tank from escaping into the outlet.

Maintenance of the EKOL 4 sewage treatment plant

EKOL series wastewater treatment plants are designed to be maintenance-free. Daily servicing is not necessary and their operational capability remains unaffected unless the power supply is interrupted. The treatment plant requires only once a year to pump out the stored sludge and twice a year to lubricate the bearings.

Where the wastewater treatment plant with EKOL 4 tank is used

EKOL all-plastic mechanical-biological wastewater treatment plants are most commonly used to treat sewage from residential sites such as apartment buildings, or from recreational facilities, hotels, campgrounds, welfare facilities, farms and factories for 25 equivalent persons.

The initial basis for the design and installation of the WWTP is the requirements of the water authorities for the quality of the water in the relevant watercourse into which the treated wastewater is discharged, the requirements of the investors and the planning authorities.

Technical data of the EKOL 4 wastewater treatment plant

| Unit | EKOL 4 | |

| Equivalent. Residents | EO | 25 |

| Daily water flow |

m3/day |

4,0 |

| Daily BOD5 contribution | kg/day | 1,6 |

| Water depth | mm | 2 000 |

| Total usable volume | m3 | 9,4 |

| Volume of settling (sludge) space | m3 | 6,2 |

| Volume of active space | m3 | 2,0 |

| Volume of existing space | m3 | 1,2 |

| Dosaz. area of the tank | m2 | 1,1 |

| RBC rotor area | m2 | 251 |

| Rotor speed | RPM | 5,2 |

| Engine power | W/400 V | 120 |

| Total weight | kg | 1 200 |

| Technical data | ||

| Length | mm | 2 500 |

| Width | mm | 2 160 |

| Tank height | mm | 2 500 |

| Total height | mm | 2 850 |

| Inlet height | mm | 2 130 |

| Outlet height | mm | 1 880 |